Expertise in

Our know-how in the field of lighting and lighting technology is particularly comprehensive. We develop, produce, and procure complete LED lights as well as individual components. The many years of expertise our employees have in this industry is one of our core competences.

When we take on complete lighting projects, customers usually contact us with a design and initial sketches. In this phase, we work out the key features of the desired light fixtures and define the design based on the quantity and market positioning required together with the customer. All product adaptations and customer-specific developments are created in our engineering department. In the case of individual components and assemblies, it is also possible for us to get involved at a later stage and plan the industrialization on the basis of STEP files and workshop drawings.

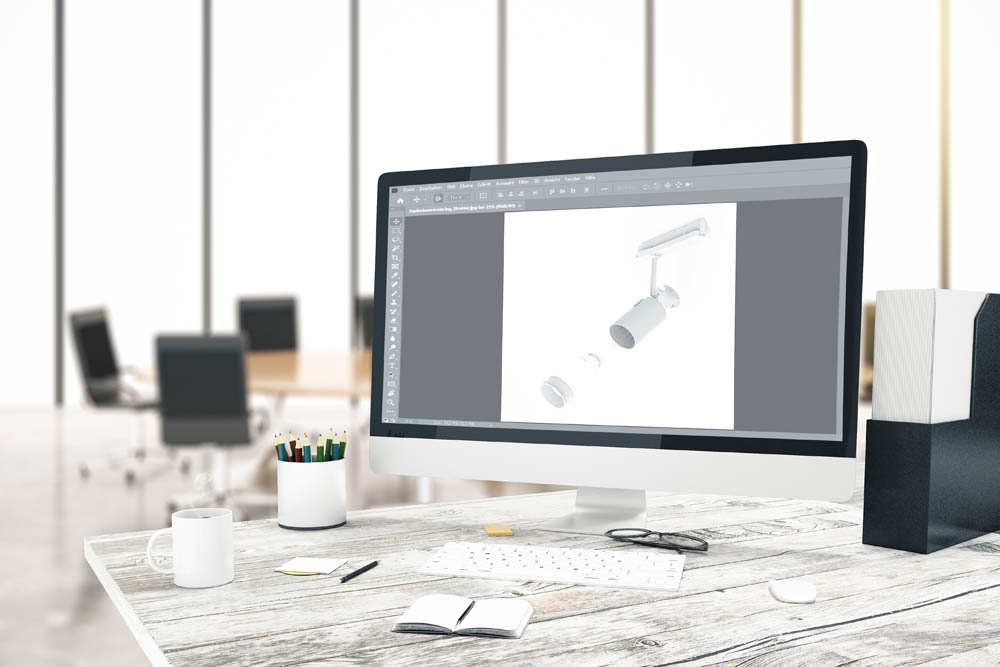

You will work together with our growing team of specialists in the fields of mechanics, electronics, lighting and thermotechnology. The creative possibilities are endless when it comes to developing your customized solutions! We advise you on the area of application, materials, coatings, IP protection classes (especially for outdoor lighting), and technical lighting properties based on your specifications. We then present you with design solutions including 3D visualizations.

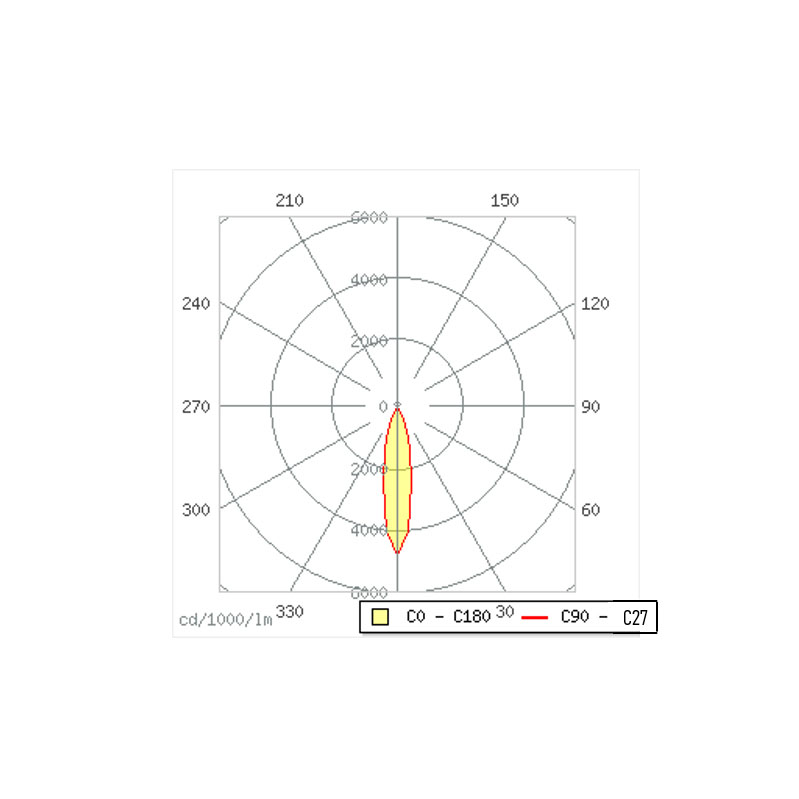

On request, we can also carry out photometric tests and measurements in our in-house light laboratory or with external specialists. Certifications and tests according to country-specific standards, such as CE testing for Europe, CCC certification for China, and UL certification for the USA, form part of our range of services and we will be happy to take care of this for you.

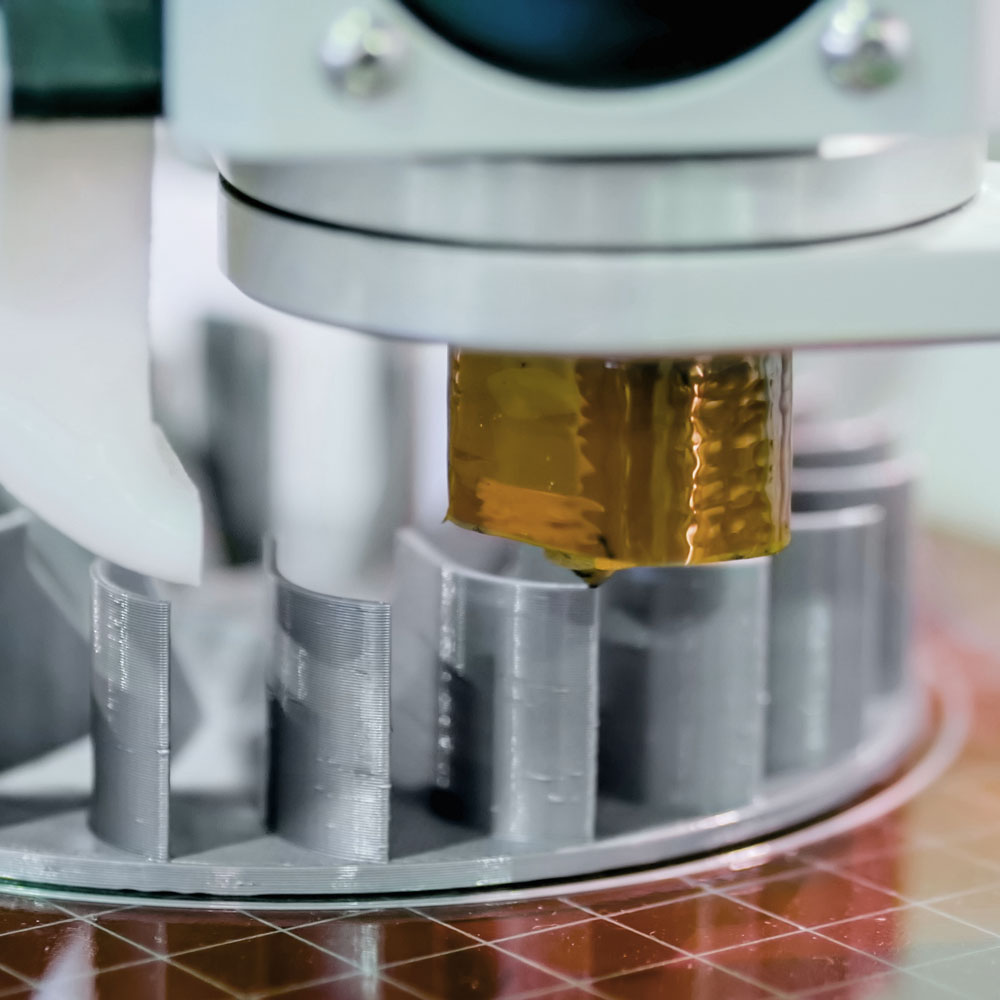

After the design and development phase, prototypes are created to verify the specifications using mechanical manufacturing and/or additive manufacturing, such as 3D printing. If necessary, we define improvements and changes together with you. Once the prototype has been approved, we start producing the tools. The initial first-out-of-tool parts will be checked again. Through these permanent control loops and coordination with a central contact person, we guarantee efficient implementation for satisfied customers.

Which production methods we use depends on the design and the area of application as well as on the planned number of units of the light. Unlike standard components, individual components are produced using pressure die casting and plastic injection molding, as well as sheet metal bending and mechanical manufacturing. Depending on the customer requirements, we carry out surface treatments such as anodizing, vacuum evaporation, powder coating, or wet painting.

The individual components are brought together on the assembly line of our production facility. Here, outdoor and indoor lights, such as recessed light fixtures and pendant fixtures as well as shop spotlights and bollard light fixtures, are assembled. High quality standards and precise workmanship are the top priority. We handle your project as a single point of contact in your language and time zone to give you peace of mind during the entire process.

Our portfolio in the lighting sector ranges from individual components, such as reflectors and lenses, through specific LED boards, housing components, and assemblies, to complete products. We deliver individual components or finished products worldwide to the agreed destination according to the customer requirements.

This email address is being protected from spambots. You need JavaScript enabled to view it.

astria - The company

Our team