Expertise in

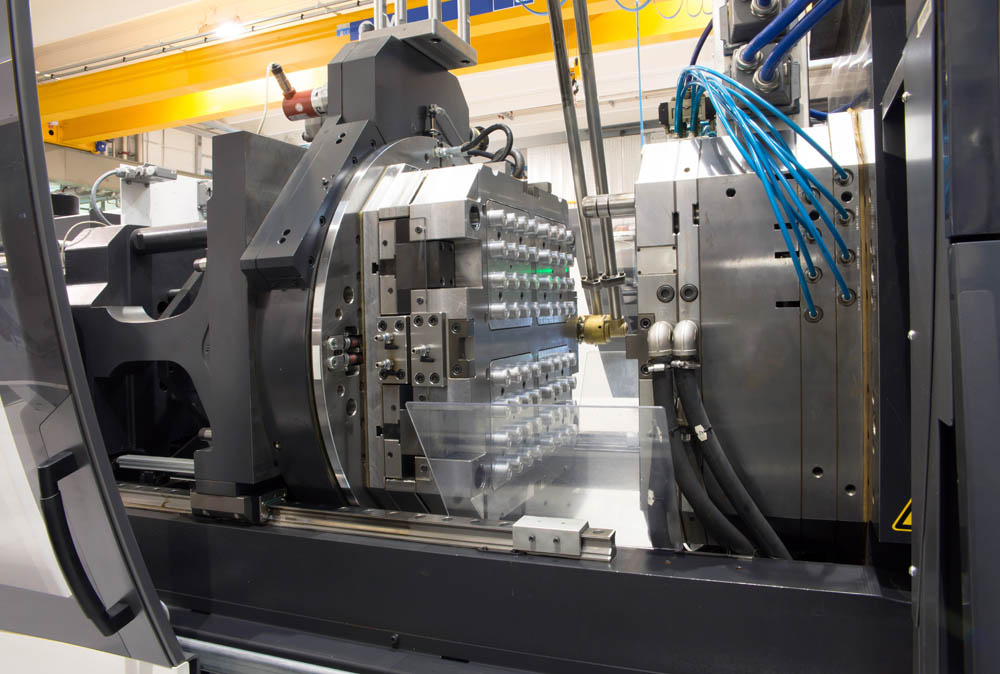

Our most frequently used technologies in the mechanical engineering sector are die casting, plastic injection molding, sheet metal processing and mechanical processing. The pay-back period of a machine tool plays a significant role, especially with die cast and plastic injection molding parts. With our competitive tooling costs, we can significantly shorten the pay-back period compared to European suppliers.

Our network for the mechanical engineering sector is primarily located in the Asia region. The supply chain density is a significant advantage, particularly in Asia. Short transport routes make workflows more efficient. For special requirements, we draw upon partner companies in eastern Europe, Germany and Austria.

This email address is being protected from spambots. You need JavaScript enabled to view it.

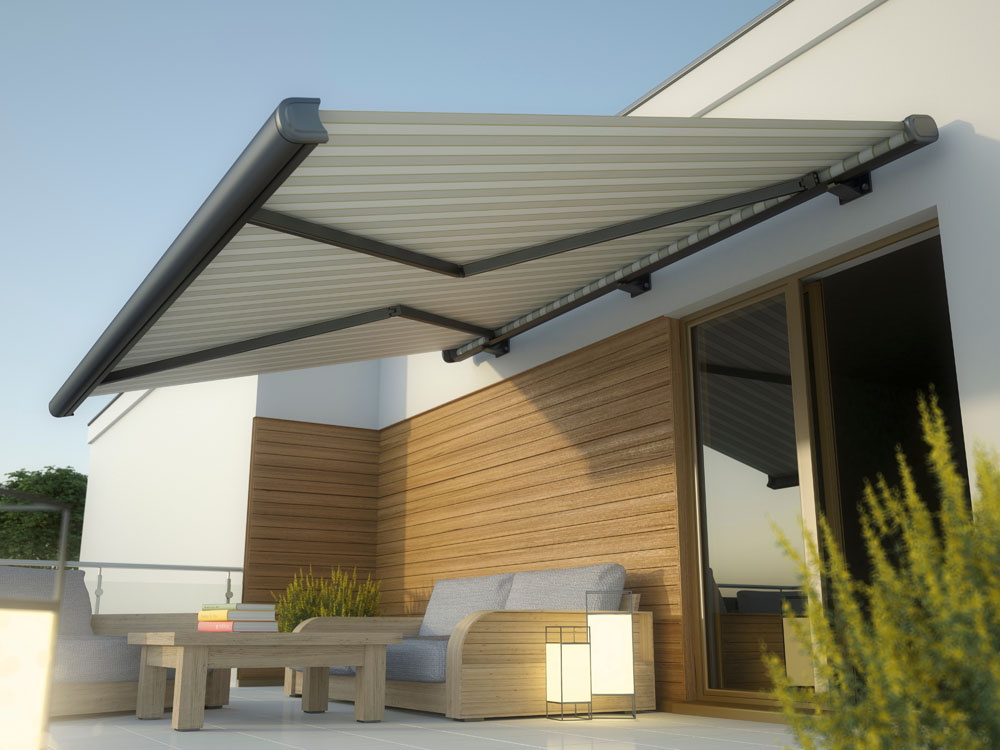

Best Practice: Sunshade Manufacturer

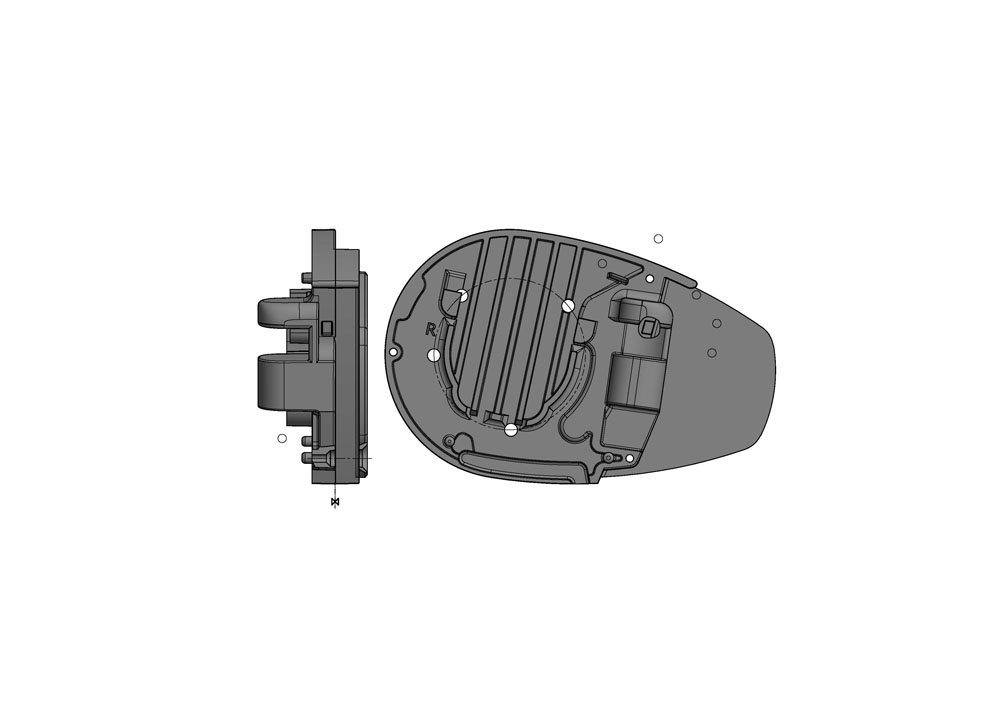

The joint of the awning is manufactured by astria using pressure die casting. Thanks to our cost-effective tools, this production method is the perfect choice for a batch size of 1000 units. Pressure die casting allows joints and the covers to be manufactured that are resistant, durable, and of a high quality. The surface is glass bead blasted after mechanical processing. All parts are manufactured to ISO 9001 standards.

At the beginning of a project, customers often contact us with an initial design drawing or concept. We then draw up a DFM (Design for Manufacturing) analysis and agree on the most important parameters such as interface lines, injection points, visible areas, and surfaces. In addition, we jointly define the quality criteria according to which the parts will be assessed for acceptance at the end of the process – after all, high quality and satisfied customers are the top priority for astria.

In the Moldflow analysis, we simulate all phases of the pressure die casting process from material injection to holding pressure. Here the material flow, temperature curves, and cooling are simulated in order to analyze shrinkage, warpage, sink marks, weld lines, and air inclusions in advance. This forms the basis for the necessary corrective measures to be adopted in the design or process. As a result, we are able to prevent tension and surface errors, and to meet the dimensional and aesthetic requirements of the customer from the very beginning.

"Together with astria, we have already implemented numerous pressure die-cast components and have always been satisfied with the results. We value reliable partners like astria, who place great emphasis on product quality and adherence to delivery dates."

Purchasing Manager, Graz-based sunshade manufacturer

astria - The company

Our team